Resin Bonded Diamond and CBN Grinding Wheels

| Grinder Type | |

|---|---|

| AKEMAT | |

| BORAN | |

| DROZDOWSKI | |

| GÖCKEL | |

| HEDER | |

| KUCHARCZYK | |

| LAKFAM | |

| LOROCH, SCHMIDT-TEMPO | |

| MAKITA | |

| REFORM | |

| UT.MA | |

| VOLLMER | |

| WALTER | |

| WEINING | |

| WIDMA | |

Common on the market of super hard tools, resin-bonded diamond and CBN grinding wheels are based on curable phenol formaldehyde resins. Resin bonds clearly display their resistance to impact loads and sensitivity to higher temperatures, at which their wear and tear intensifies. In addition, Diamentpol offers polyamide-resin-bonded diamond and CBN grinding wheels. This type of grinding wheels is characterised by a much higher (than standard ones) thermal resistance as well as increased performance and efficiency of grinding. As a result, the longevity of such wheels is extended by approx. 40–45%. The most often, the polyamide resin bond has been applied in the following types of grinding wheels: VB8®, VD14® triple, 1A1, 1V1, 11V9, 12V9, 14A1, 14F1.

Electroplated CBN Grinding Wheels

CBN grinding wheels for sharpening band saws

| MARKING | SAW PROFILE | DIAMETER D [mm] | HEIGHT T [mm] | ORIFICE H [mm] |

|---|---|---|---|---|

| Profil F | Fenes | 127 | 22,2 | 12,7 |

| 150 | 22,2 | 20 | ||

| 203 | 22,2 | 32 | ||

| Profil RM | Ro-Ma | 127 | 22,2 | 12,7 |

| 150 | 20 | 22,2 | ||

| 203 | 22,2 | 32 | ||

| Profil S | Sword | 127 | 9 | 12,7 |

| Profil WM | Wood-Mizer 10/30 | 127 | 22,2 | 12,7 |

| 150 | 22,2 | 20 | ||

| 203 | 22,2 | 25,4 | ||

| 203 | 22,2 | 32 | ||

| Profil WM WINTER | Wood-Mizer 9/29 | 127 | 22,2 | 12,7 |

| 203 | 22,2 | 25,4 | ||

| 203 | 22,2 | 32 |

Electroplated grinding wheels have a single layer of CBN grit and are characterised by a greater protrusion of the grit from the bond and high efficiency, which decreases as the grit is blunted.

Electroplated CBN grinding wheels require the use of a coolant.

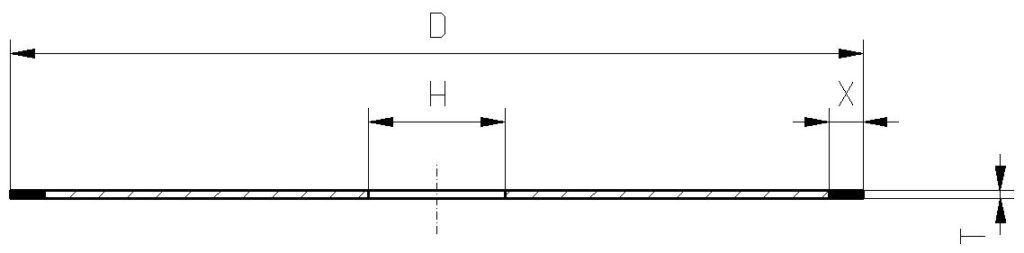

Grinding Wheels for Cutting

Grinding Wheels for Cutting

1A1R

Resin-bonded diamond grinding wheels are used for cutting sintered carbides, technical ceramics, plastics and laminates, as well as quartz glass.

Metal-bonded diamond grinding wheels are used for cutting glass, crystals, ceramics, hard magnetic alloys, precious and semi-precious stones, as well as refractories. Metal-bonded grinding wheels require the use of a coolant.

Resin-bonded CBN grinding wheels are used for cutting cured metal alloys, bearing steel, high-speed steel, heat-resistant steel and magnetic steel.

Diamond Dressers

Different diamond dressers can be used in the housing with the Morse taper1

Regeneration of Diamond Dressers

Regeneration of the worn diamond dresser consists in fully restoring its usefulness

Having completed proper technological procedures (after soldering the diamond crystal in the housing or after grinding), the dresser can be used in production processes again.

The following items are subject to regeneration:

- single-point rough diamond dressers

- single-point ground diamond dressers

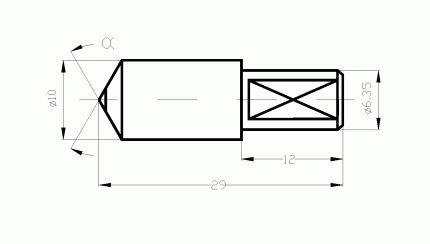

Diamond Hardness Testers

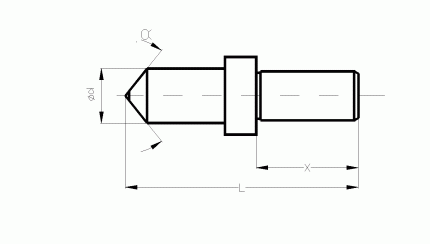

Diamond Hardness Testers are intended for hardness measurement. The diamond which is the work piece of the indenter is ground to a geometric – conical or pyramidal – shape.

| Rockwell | ||

|---|---|---|

| typ/type | α | kt |

| A | 120° ± 0.35° | 0,25 |

| C | 120° ± 0.35° | 0,11 |

| Vickers | ||||

|---|---|---|---|---|

| typ/type | α | Ød | X | L |

| I | 136° ± 30° | 5 | 30 | 22 |

| II | 136° ± 30° | 7 | 12 | 29 |

Diamond Pastes

Diamond pastes are intended for final machining, as well as manual and machine lapping and polishing metals, alloys and non-metallic materials.

Pastes differ in their sizes and percentage content of diamond grit.

| WEIGHT CONTENT OF DIAMOND GRIT [%] | SURFACE ROUGHNESS (RA) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DIAMOND GRIT SIZE | NOMINAL SIZE [μm] | LOW | NORMAL | BEFORE MACHINING | AFTER MACHINING | ||||||||||

| D46 | 40/28 | 10 | 20 | 0,200 | 0,155 | ||||||||||

| D25 | 28/20 | 10 | 20 | 0,160 | 0,120 | ||||||||||

| D16 | 20/14 | 10 | 20 | 0,125 | 0,095 | ||||||||||

| D12 | 14/10 | 10 | 20 | 0,100 | 0,075 | ||||||||||

| D8 | 10/7 | 10 | 20 | 0,080 | 0,060 | ||||||||||

| D6 | 7/5 | 10 | 20 | 0,063 | 0,045 | ||||||||||

| D4 | 5/3 | 10 | 20 | 0,050 | 0,038 | ||||||||||

| D2 | 3/2 | 10 | 20 | 0,040 | 0,32 | ||||||||||

| D1 | 2/1 | 10 | 20 | 0,032 | 0,023 | ||||||||||

A diamond paste should be stored at a temperature of 25°C ± 5°C. The paste viscosity decreases at a higher temperature, which can lead to the paste losing its homogeneity and, therefore, to the lower quality of processing.

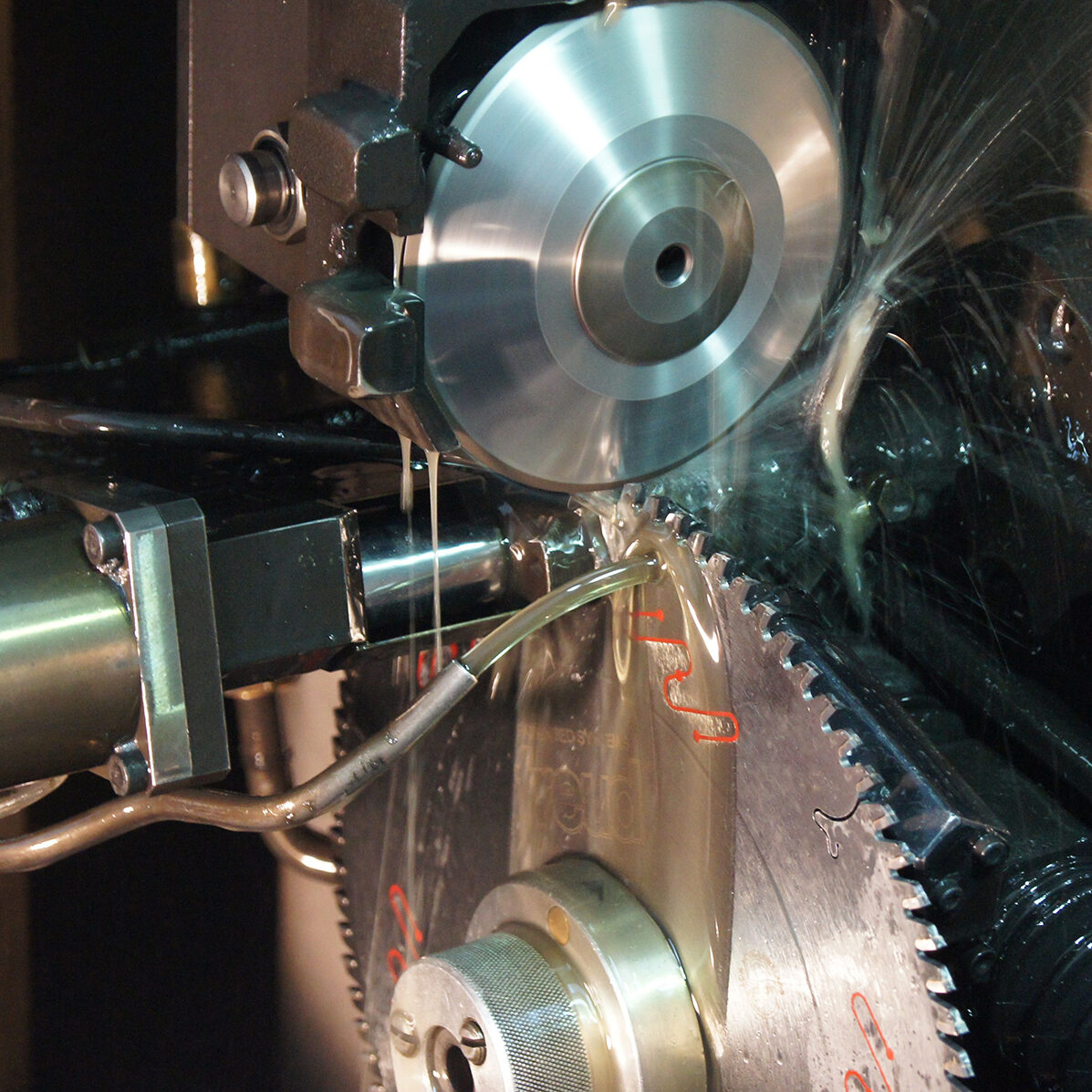

Cooling

Whenever and wherever possible, cooling is recommended. It positively impacts the grinding process and durability of a grinding wheel.

For cooling CBN grinding wheels, it is recommended using mineral oil with the addition of EP. For diamond grinding wheels, you can use water-oil emulsions characterised by the concentration between 3 and 5%.

Advantages of using coolant:

- decrease in the temperature between the grinding wheel and the material being machined (cooling),

- reduction of the friction between the grit and the material being machined (lubrication),

- removal of the grinding process product (cleansing).

Diamentpol offers two products:

- Non-emulsifiable machining oil of low viscosity. Preparation of highly refined mineral oils with additives. Contains carefully selected additives such as EP which do not contain chlorine nor sulphur and is inactive towards copper.

- Fluid for metal machining – cooling liquid. Synthetic liquid, transparent, miscible with water. Creates transparent aqueous solutions of green colour. Developed so that specific requirements are fulfilled as regards occupational health and environmental protection. The product does not contain nitrates, boron nor amines. Recommended concentration: 3 to 5%.